Technical problem definition

Conventional sandwich structures with foam or honeycomb cores have limitations in terms of local load application and introduction of impact loads, shear strength, service life under vibration loads and plastic deformability. These often lead to core shear fractures or delamination under high loads and failure under vibration loads. In addition, conventional manufacturing processes are energy-intensive and offer only limited opportunities for material savings and functional integration.

The challenge

The development of a highly resilient, multifunctional sandwich composite requires a structural concept for the core composite that is simultaneously lightweight, rigid, energy-absorbing and efficient in terms of production technology. The challenge lies in the mechanical-functional optimization while at the same time meeting sustainability targets and industrial manufacturability.

Solution and result

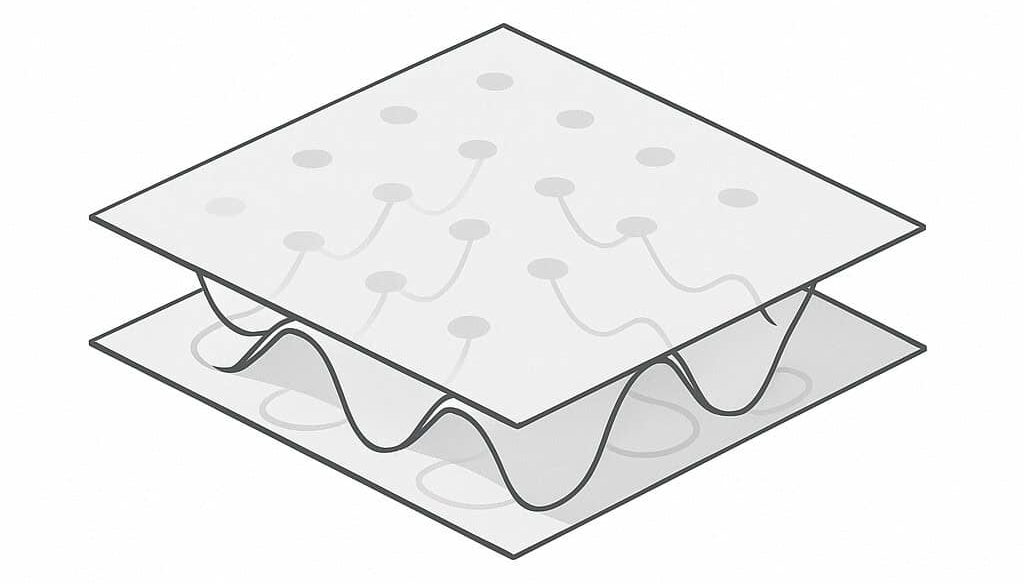

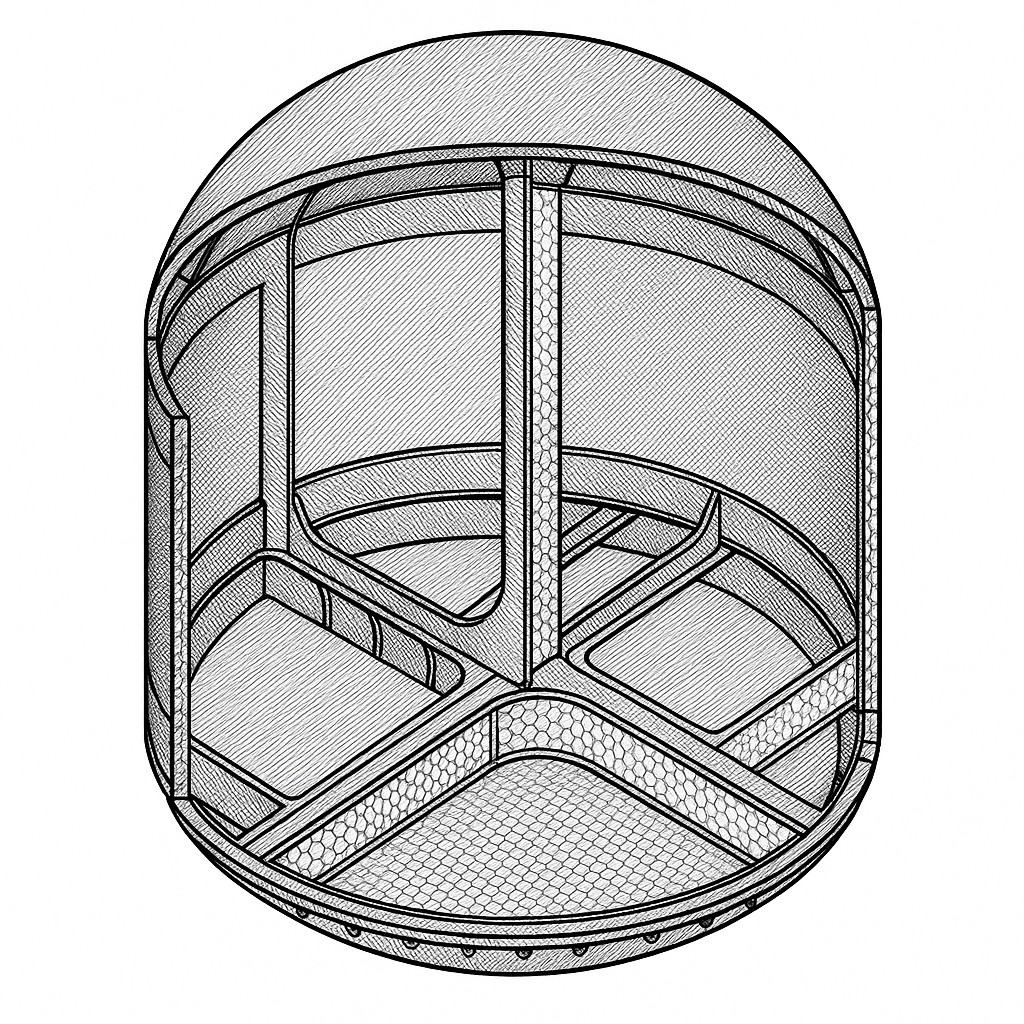

Bionic camber structuring is a new sustainable forming process that creates three-dimensional structures in thin-walled materials (fiber composites and sheet metal) through induced buckling and self-organization. The application as a core structure in a sandwich composite offers the following advantages:

- 7-fold flexural rigidity of the solitary arch structure compared to unstructured material

- Isotropic stiffness distribution

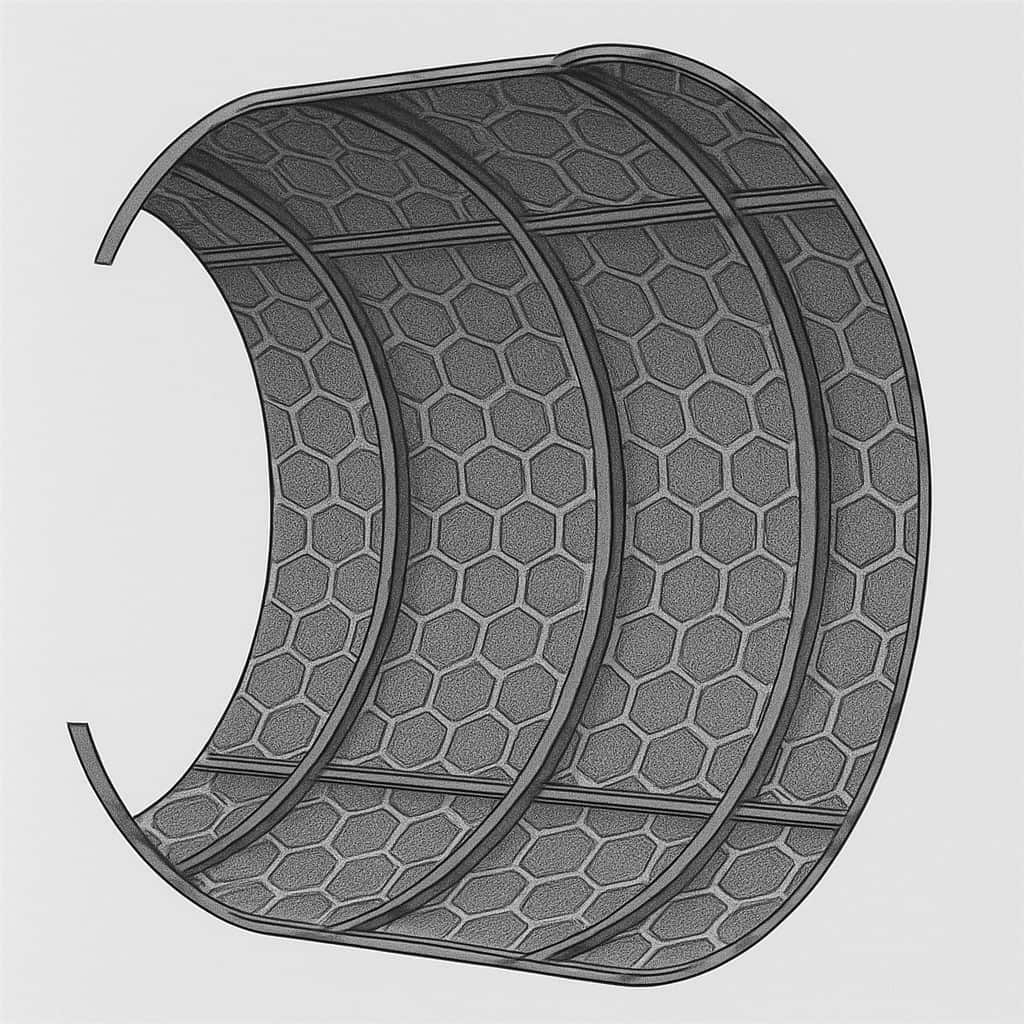

- High energy absorption and load redistribution thanks to DeepHEX core molds

- Open core structure - no moisture accumulation

- Mechanically resilient connection by spot or surface bonding, riveting or welding

- Scalable production through industrial processes

The multi-parameter sandwich structure with a bionically curved core allows controllable bending, torsional and shear stiffness thanks to the targeted arrangement of the connection points. Studies show a potential weight reduction of up to 50 % with comparable stiffness to conventional sandwich systems.