Dr. Mirtsch GmbH -

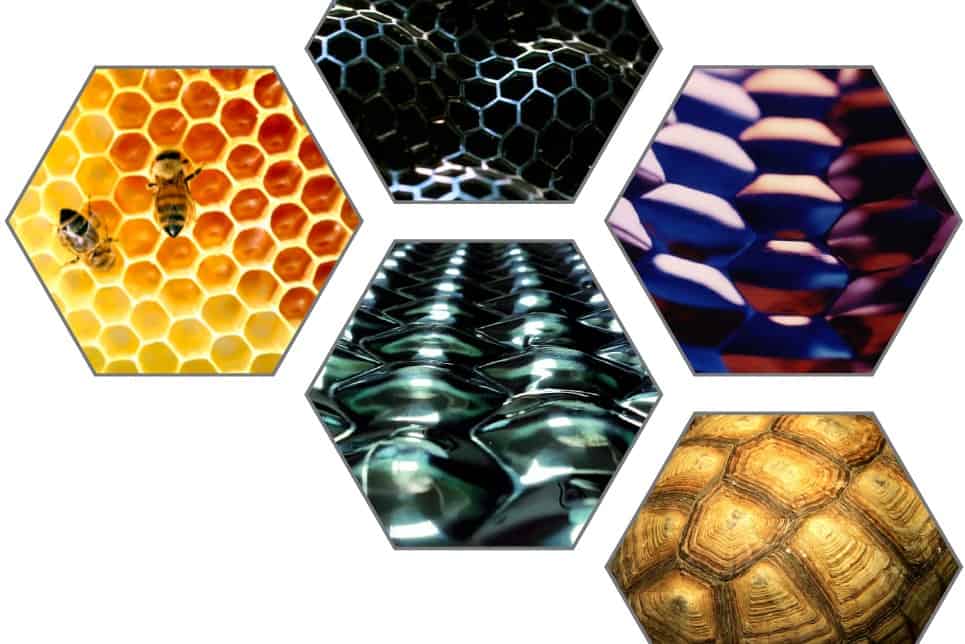

Bionic lightweight vault structures based on self‑structuring for a sustainable future

Your partner for sheet metal with ultra‑thin wall thicknesses.

The advantages of vault‑structured materials

Bionic vault structures

Higher multi‑axial bending stiffness

Less material weakening due to fundamentally different forming process.

Lighter – approx. 20 % material savings

Weight savings and lower material costs.

Only a fraction of the forming energy required

This means more forming reserves for further processing.

Sustainable – from nature for nature

Less energy consumption, material usage and weight.

Redistribution of forming energy / reduction of local loads

Less energy consumption, material usage and weight.

Improved acoustic damping behaviour

Higher

Enhanced thermal and flow behaviour

Gentle forming, so that painted sheet metal, for example, can be formed.

Favourable crash & impact performance

Less energy consumption, material usage and weight.

Very high plastic‑forming reserves

Less energy consumption, material usage and weight.

High buckling stability

Especially with vibrating loads.

Compensation of thermal stresses

Especially with vibrating loads.

Preservation of surface quality

Gentle forming, so that painted sheet metal, for example, can be formed.

Diffuse light reflection

Gentle forming, so that painted sheet metal, for example, can be formed.

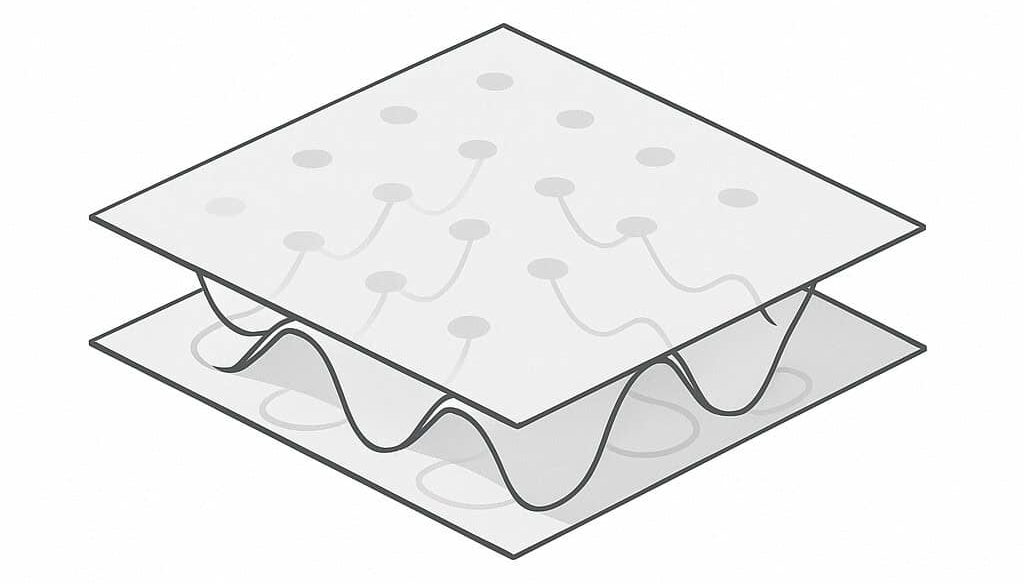

What exactly is a vault structure?

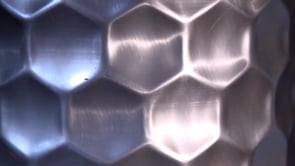

Vault structuring is a forming process that introduces mostly hexagonal, three‑dimensional vault structures into thin‑walled materials such as sheet metal, plastic film, cardboard or paper.

Unlike conventional sheet‑metal forming methods (e.g. embossing, beading or hydroforming), it relies on an energy‑minimised self‑organisation process that conserves material, energy and resources. The key property is greatly increased stiffness (bending and buckling). Vault‑structured materials are products of Dr Mirtsch GmbH and are protected by numerous national and international intellectual‑property rights.

Vault‑structured materials are products from Dr. Mirtsch GmbH and are protected by numerous national and international property rights.

Bionic vault structures in video

Applications of bionic vault structuring

Automotive engineering

Vault‑structured materials are used to produce lighter components with high stiffness and crash‑energy‑absorption capability at low energy input and with outstanding sustainability.

Example: a series‑produced, bionically vault‑structured rear panel for the Mercedes SLK provides high vibration and sound damping with minimal space requirements.

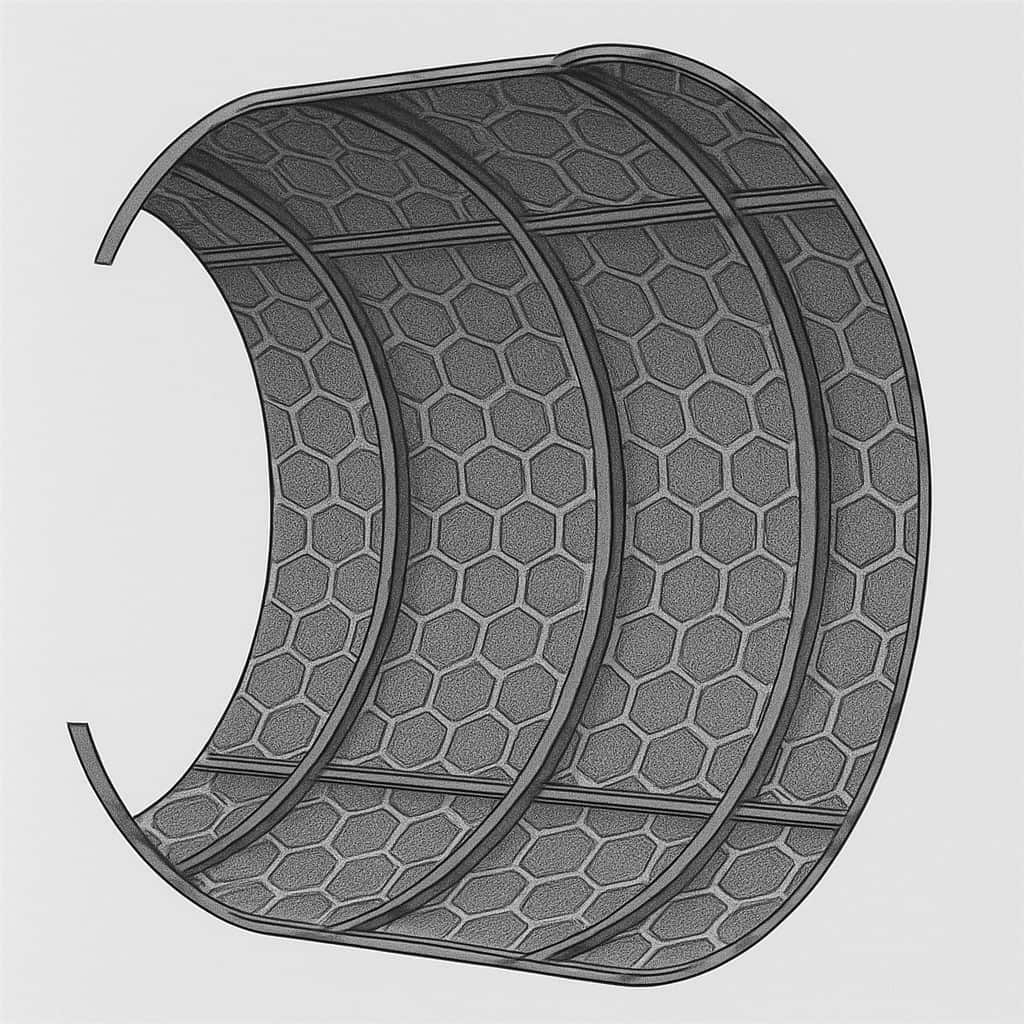

Household appliances

Miele has employed vault structures in its washing‑machine drums since the “Softtronic” generation.

According to the company, the patented honeycomb drum offers exceptional mechanical strength and gentler washing by allowing laundry to glide on a thin water film, leading to sustainable, economical and faster cycles.

Lighting technology

Siteco uses vault‑structured aluminium sheet to manufacture LED designer luminaires. Optimal light reflection delivers high light quality, and the material serves as both housing and reflector, saving ~80 % of material.

Construction & architecture

Vault structures are applied to building roofs and façades as well as construction and agricultural machinery. The “Blue Turtle” sports complex in Yuzhny Odessa (Ukraine, 2003) features a ~6 000 m² roof clad with just 0.7 mm thick vault‑structured aluminium.

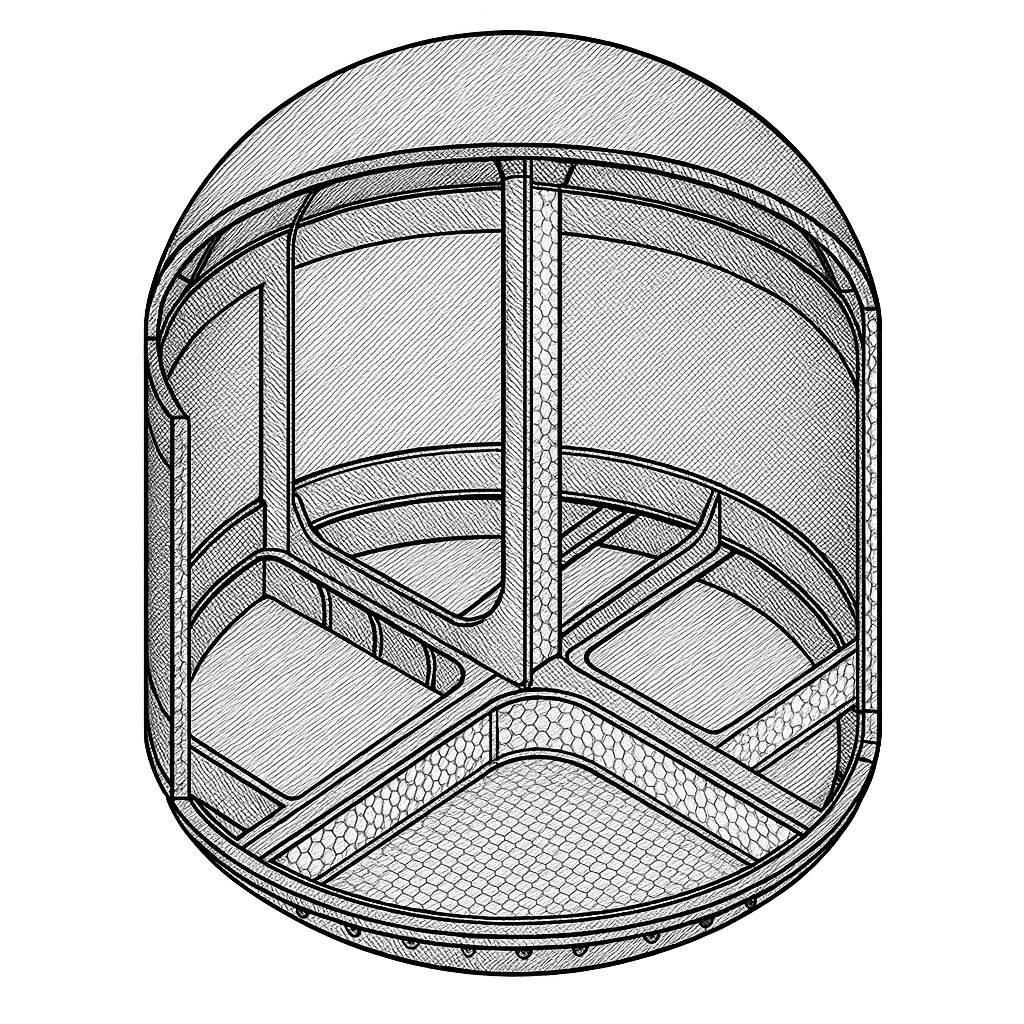

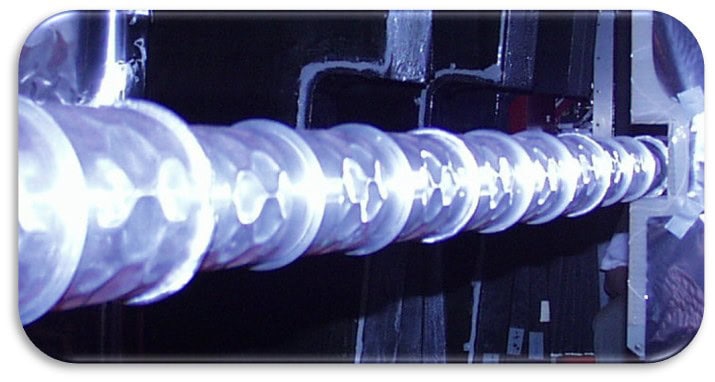

Particle accelerators

At the DESY electron synchrotron in Hamburg, a vault‑structured conical aluminium‑tube system has been operating trouble‑free for over 10 years—combining form‑stable, ultra‑thin vacuum pipes with flexibility against thermal expansion.

The synergetic properties are dimensionally stable, extremely thin tubes under high vacuum stress and flexibility when thermal expansion is restricted.

About Dr Mirtsch GmbH

The story since the 1970s

Mid‑1970s: Prof. Dr. Frank Mirtsch discovers the self‑stiffening effect of vault structures through the accidental, nature‑like structuring of a thin cylinder.

Continuous development leads to vault structuring technology; Dr Mirtsch Vault Structure GmbH is founded in 1993 as a development company, expanded in 1997 with a production arm.

Since 2003 the family‑run company has held 30+ national and international patents and several innovation awards.

In 2023 Prof. Mirtsch retired from operations and now acts as senior expert. Dr Mirtsch GmbH is run by the Koller family together with TGM Lightweight Solutions GmbH .

Technology ideas

What's new with UNS