Technical problem definition

Machine cladding must remain structurally stable under high acoustic and mechanical loads, while at the same time the requirements for weight, rigidity and durability increase. Classic sheet metal cladding quickly reaches its limits in terms of noise reduction and energy absorption under crash loads. The search is on for a solution with:

- High specific stiffness (E/ρ)

- High acoustic damping effect

- High energy absorption during impact and crash loads

- Low weight

- Sustainable production through reduced energy consumption

The challenge

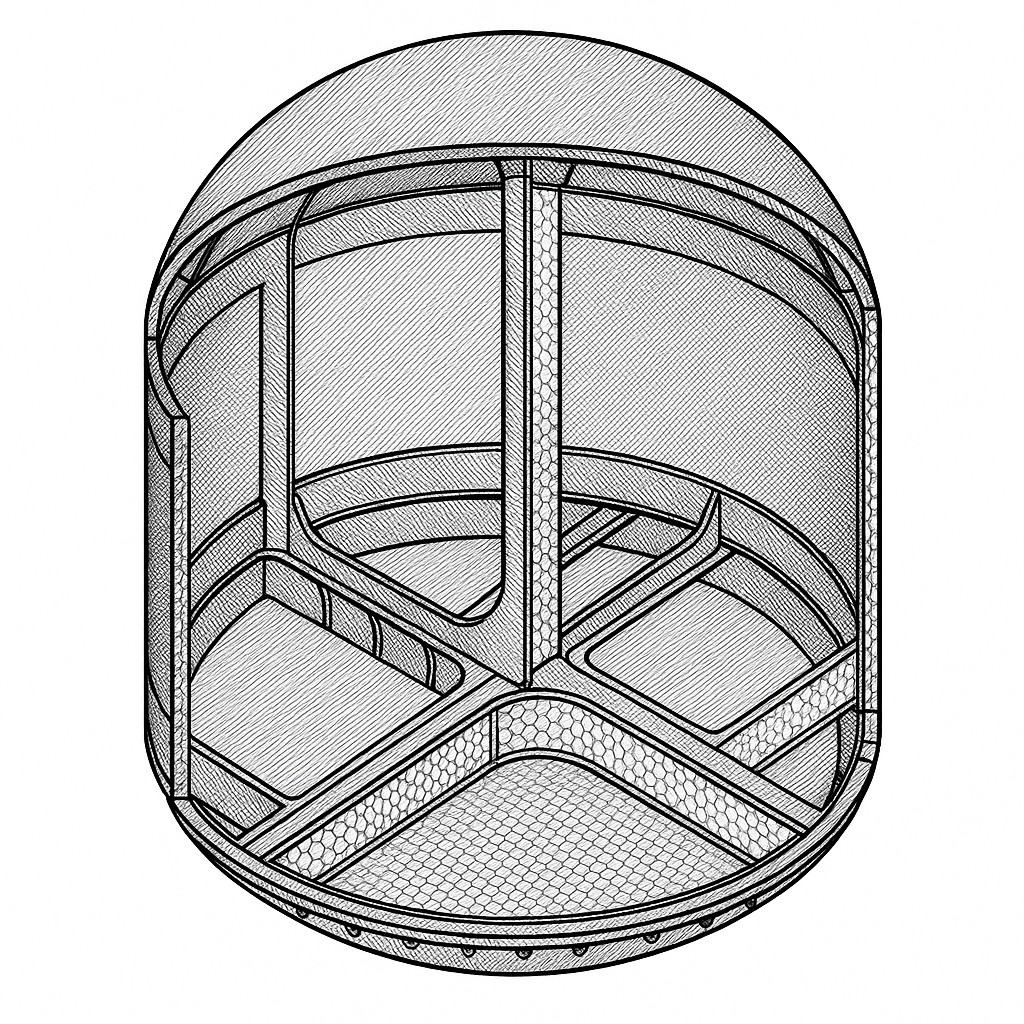

The challenge lies in integrating several functions into a modular wall structure that is as light as possible. The system must be acoustically effective, reduce local stress peaks and give way in a defined manner in the event of mechanical overload without losing its protective function.

Solution and result

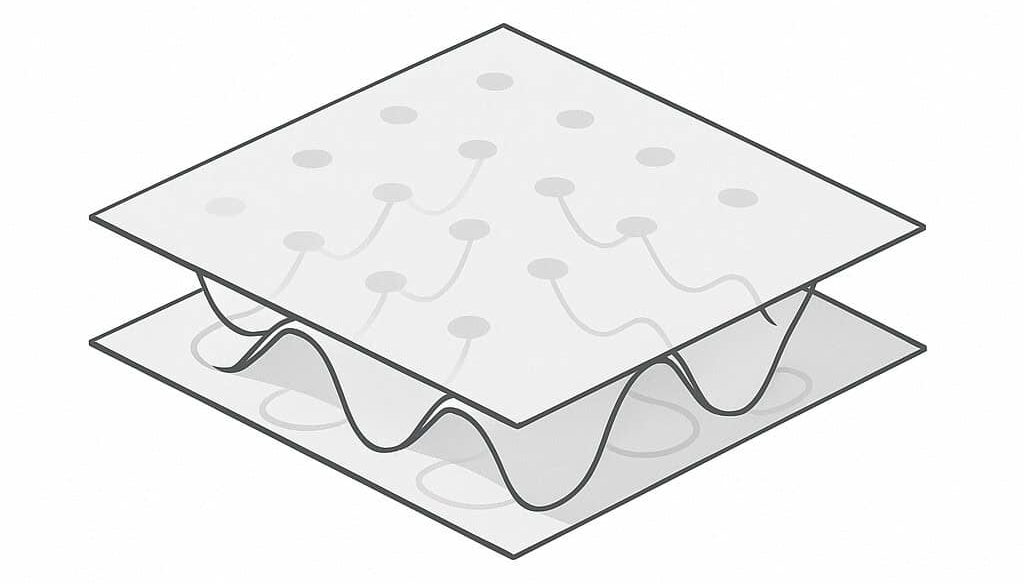

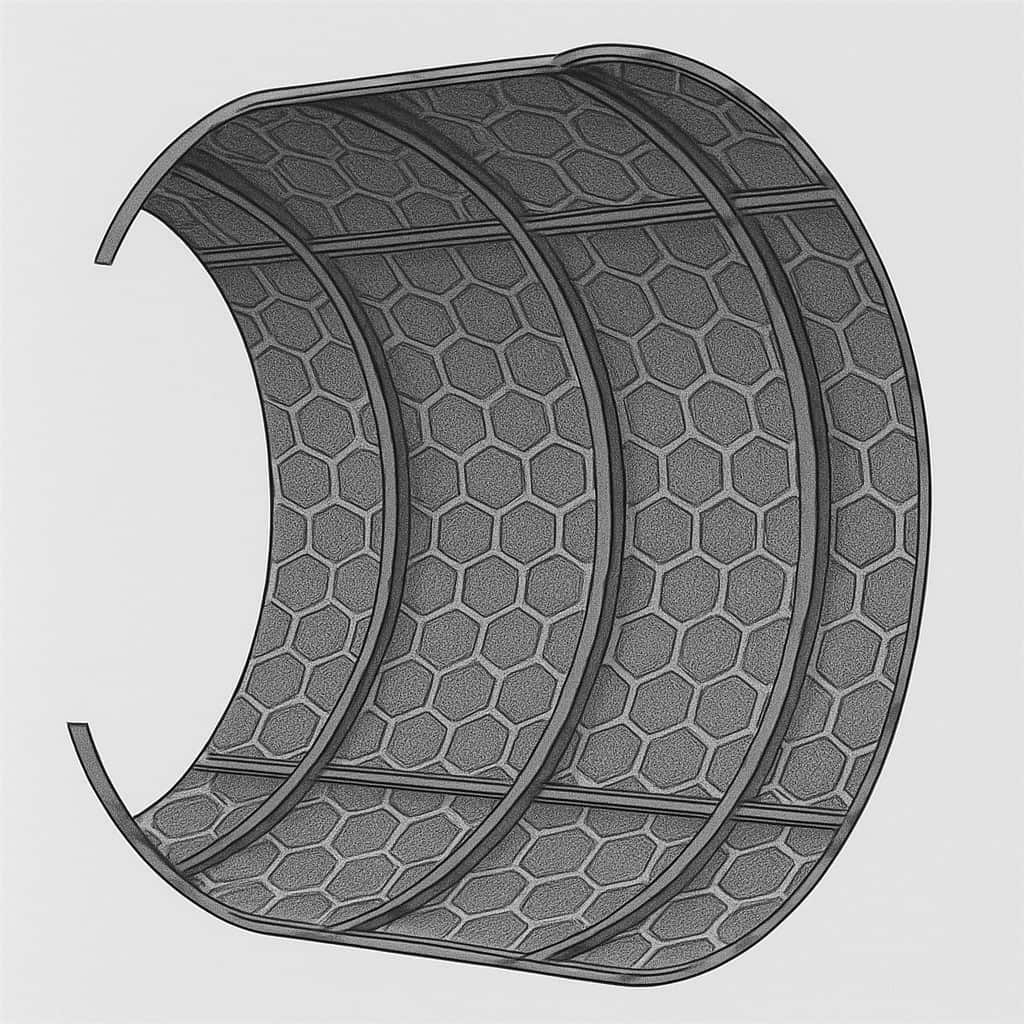

The solution is a sandwich structure with an inner camber-structured core structure as a perforated or smooth sheet (e.g. DeepHEX) and a smooth top layer as well as an optional open-cell PU foam layer for acoustic absorption. The self-organizing camber structure creates ultra-light yet highly rigid structures with the following properties:

- 7 times the bending stiffness of flat sheet metal

- Isotropic stiffness (2D)

- Uniform stress distribution

- High local energy absorption without global buckling

- High acoustic damping performance through targeted combination of geometry and material

Preliminary tests and simulations show that material savings of up to 50 % can be achieved with the same protective effect compared to conventional cladding.