Technical problem definition

Conventional hoods consist of flat or simply structured sheet metal, which must be designed with a comparatively high overall height to achieve the necessary bending stiffness and energy absorption. This leads to higher masses and limited efficiency in energy distribution in the event of a crash. They are also susceptible to local stress peaks and offer limited opportunities for functional integration.

The challenge

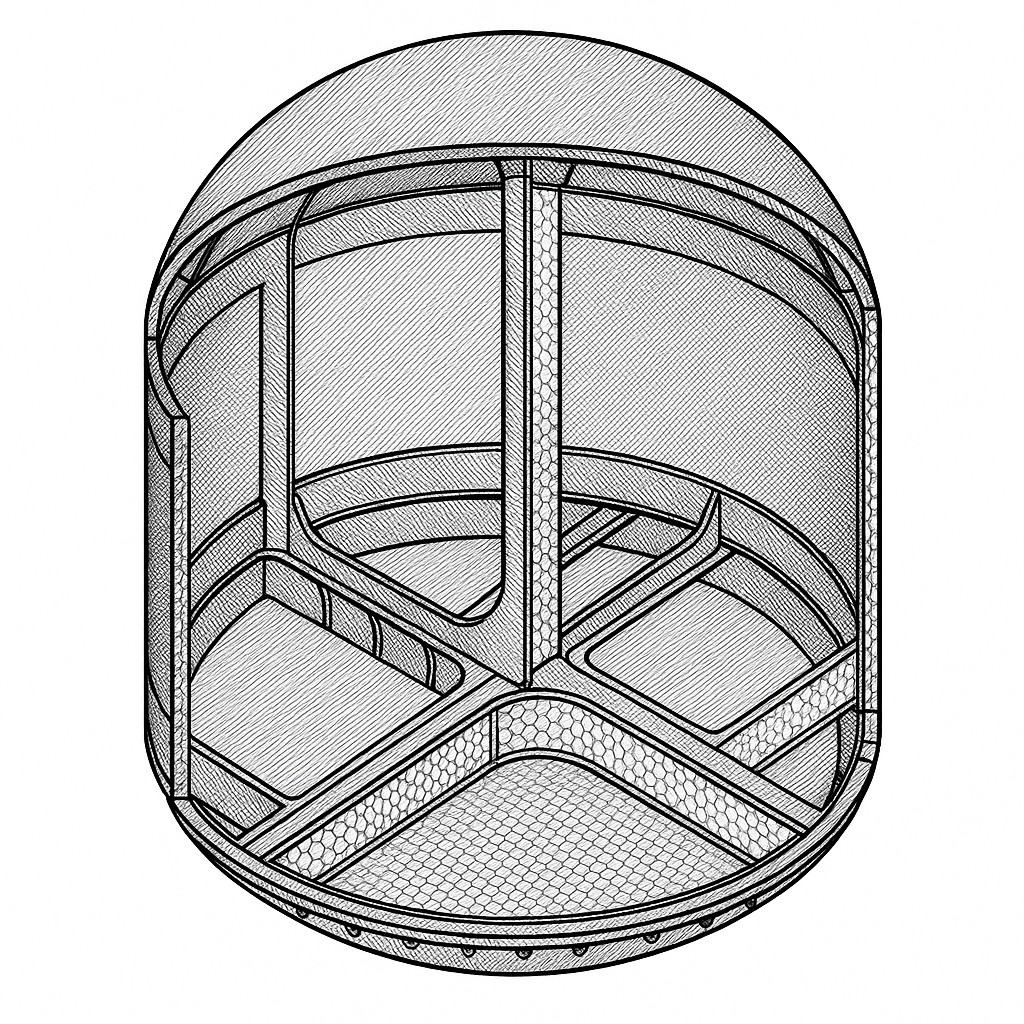

The technical challenge lies in the development of a lightweight hood with a low body height that has high rigidity and good crash performance with reduced material usage, whereby the head impact loads (HIC) can be redistributed laterally by the arched structure. At the same time, the structure must be able to withstand air loads and vibrations while remaining robust, which conventional methods can often only achieve with additional effort.

Solution and result

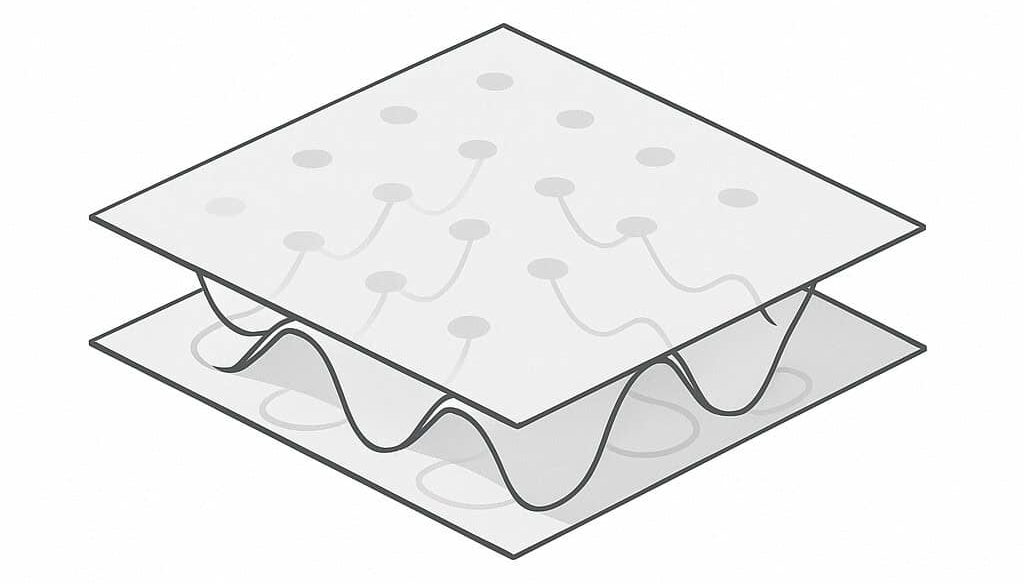

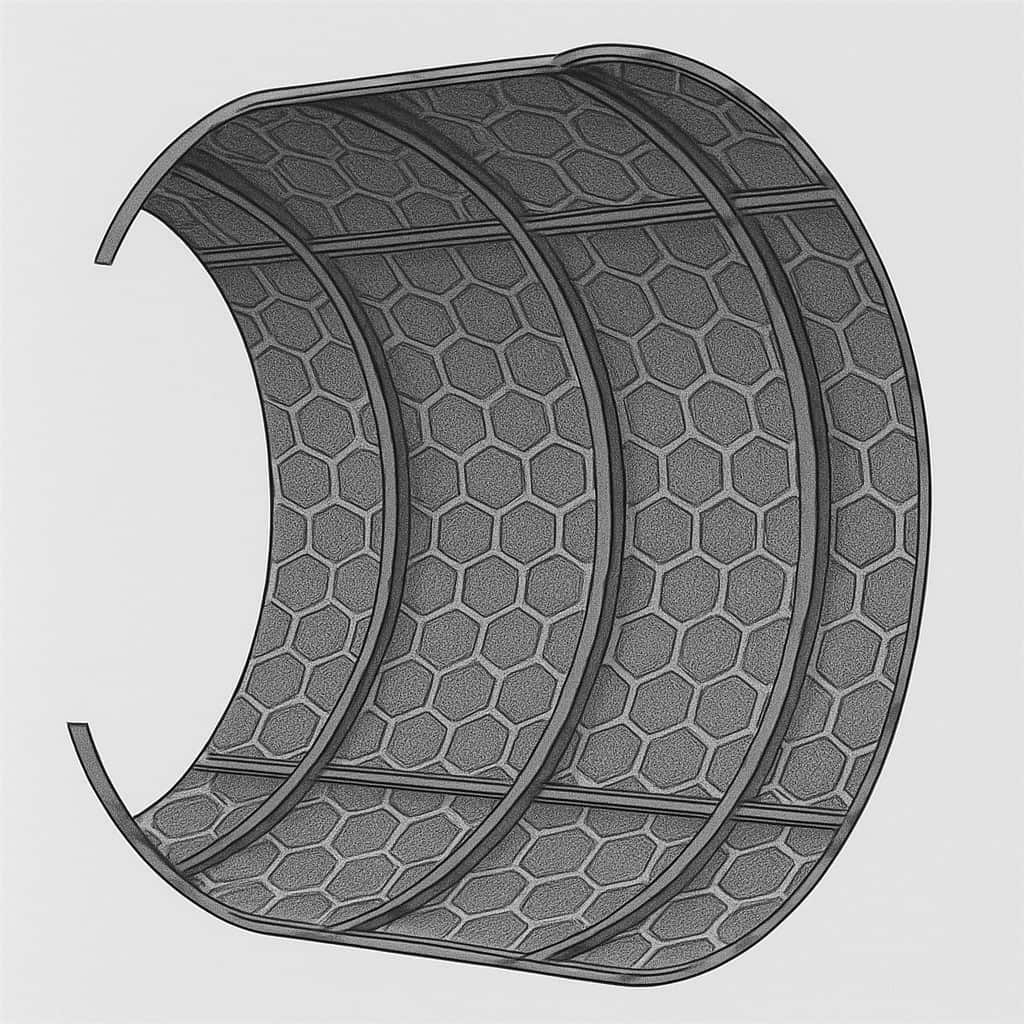

Curvature structuring according to the bionic principle enables the formation of self-organized structures with isotropic stiffness behaviour through production using the controlled buckling process. Compared to flat sheets, this results in

- up to 7 times higher bending stiffness and lateral redistribution of head impact loads (HIC)

- uniform voltage distribution to avoid voltage peaks

- significantly improved energy absorption (e.g. thanks to DeepHEX structure)

- Reduced wall thicknesses without compromising mechanical integrity

Depending on the choice of material (e.g. DC04 or AlMg3), the overall height of the hood can be reduced by around 20% and the overall mass of the hood can be reduced by up to 30% compared to conventional solutions, while at the same time improving the mechanical properties. The use of half-sandwich structures also offers functional advantages and improved utilization of installation space.

Outlook and application potential

The concept of the bionically curved structure can be flexibly applied to different geometries and load cases. In the automotive industry in particular, this opens up potential for functional integration (e.g. acoustic damping, crash energy absorption, thermal insulation) while drastically reducing mass. Implementation on an industrial scale is realistic thanks to the already patented processes and existing pilot production.