Technical problem definition

Aircraft fuselages are subject to high mechanical loads due to compressive, bending, shear and torsional forces. Conventional frame-stringer-skin designs in sheet metal composite but also in fiber composite (e.g. co-bonding) reach their limits in terms of stability, weight and production costs. In particular, local buckling failures and inefficient load paths hinder a further reduction in weight. What is required is a structure with:

- High specific bending stiffness and buckling stiffness

- Uniform stress distribution

- Effective dent support in sandwich construction

- Multifunctional load detour without additional stiffening elements

- Minimal weight and high energy efficiency

The challenge

Reducing structural mass while increasing rigidity requires new lightweight construction approaches. Conventional sandwich designs require complex production and cannot completely prevent local instabilities. In addition, anisotropic properties are a hindrance for complex load paths in airframes.

Solution and result

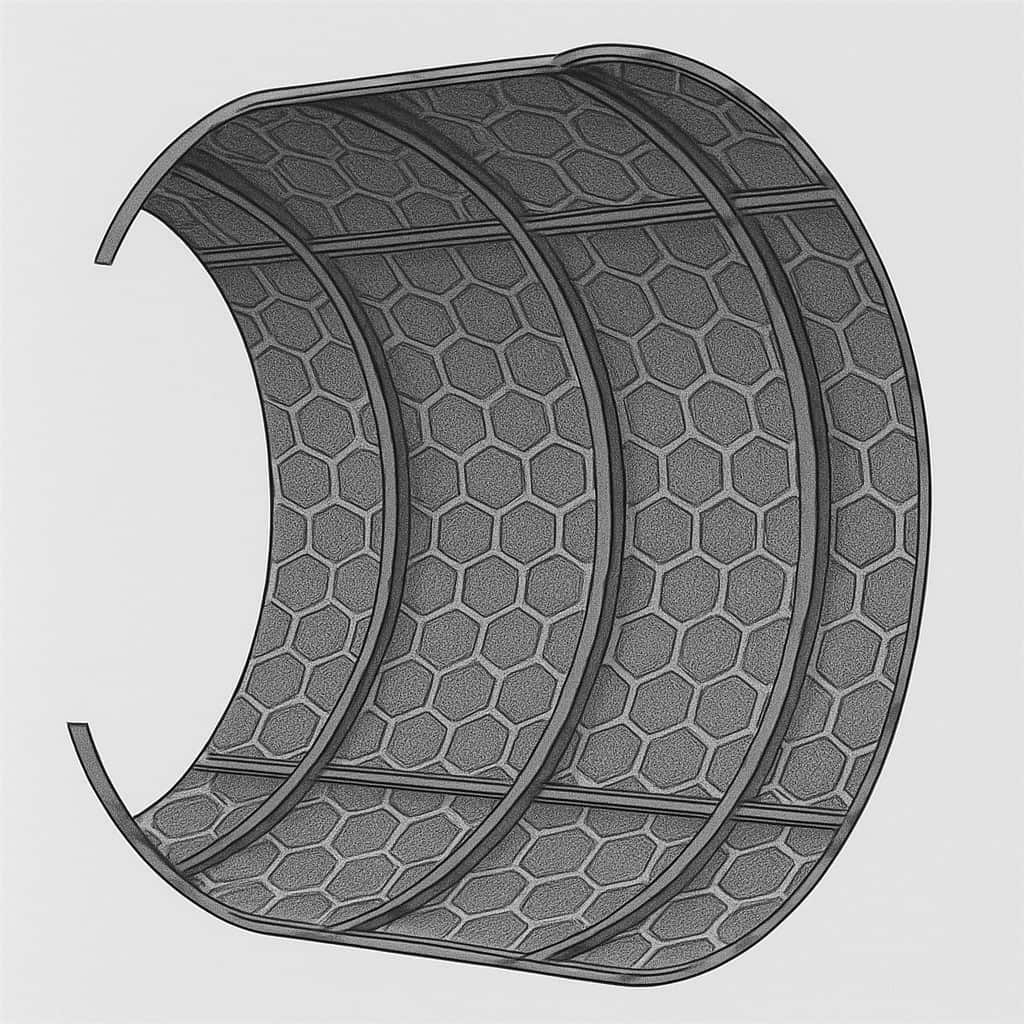

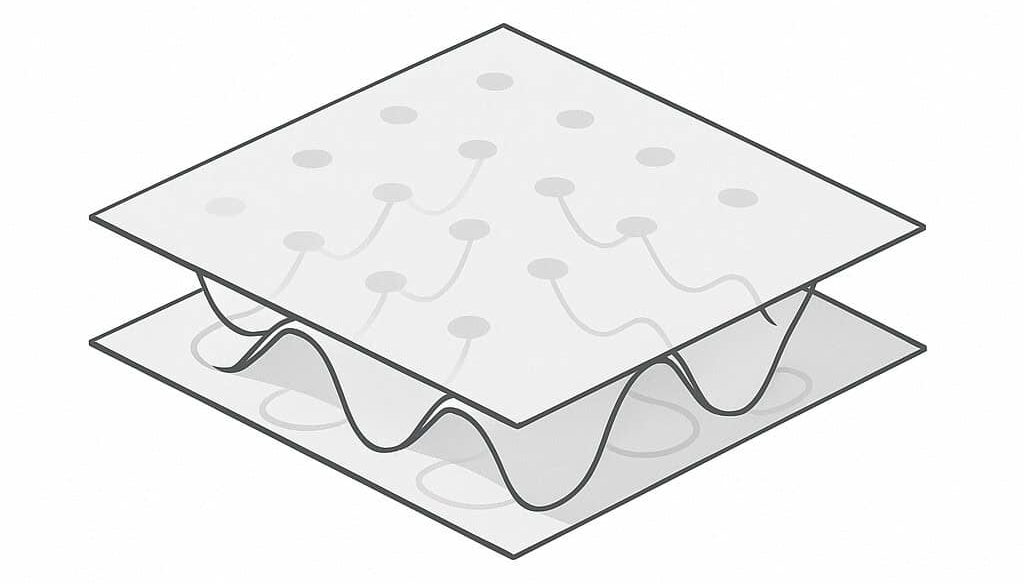

The bionic-arched half-sandwich construction method uses self-stiffening structures that are induced by controlled local buckling of sheet metal membranes or thin fiber composite structures during the curing phase. The process enables structures that offer the following advantages even without a sandwich composite:

- Up to 7 times the bending stiffness (compared to smooth sheet metal)

- Isotropic mechanical properties for targeted stiffening

- High energy absorption (DeepHEX)

- Stress relief through load-distributing core structure

- Buckling support in sandwich structures due to curved core geometry

- Weight savings of up to 50 % compared to conventional flat construction methods

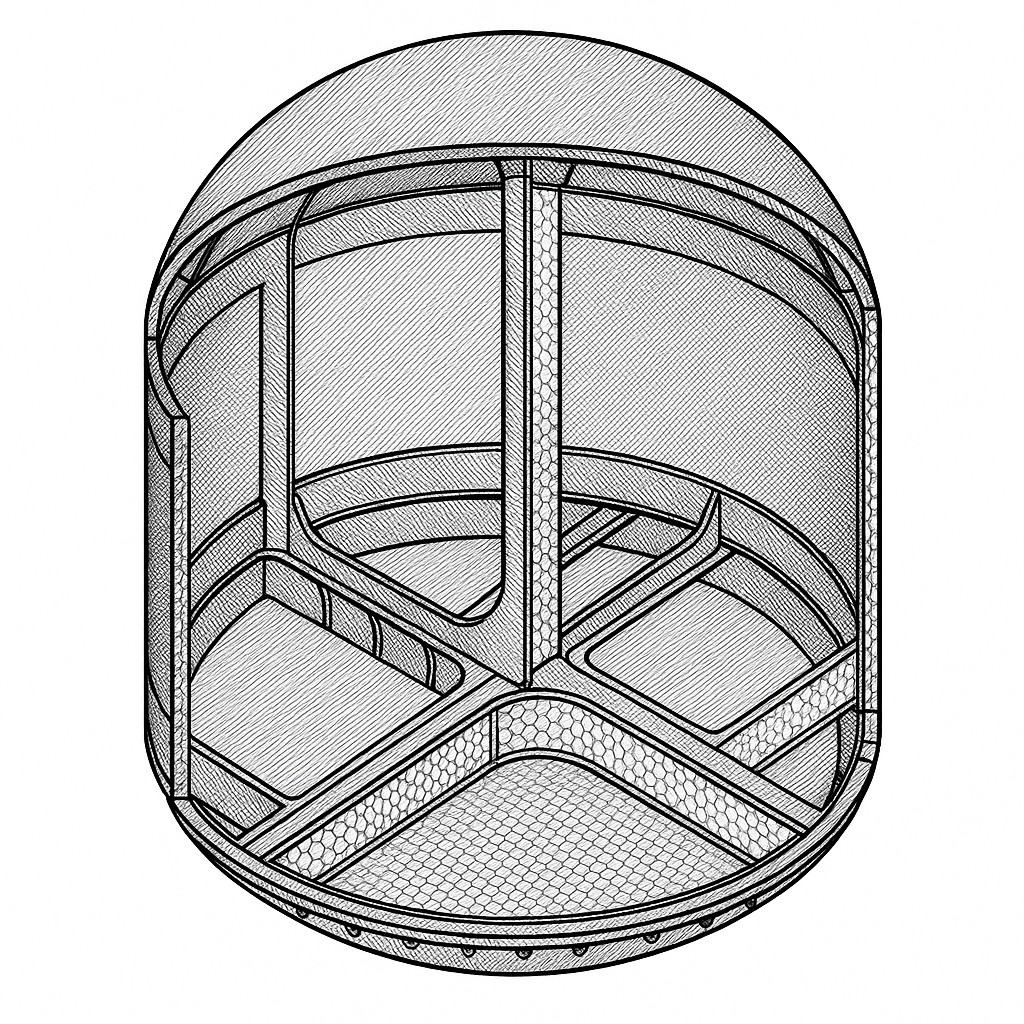

Application potential

The structural principle is ideally suited for primary and secondary structures in aircraft fuselages, especially for pressurized sections and as integral shell panel constructions. Further applications are conceivable in the area of damping behavior, cell-internal function integration and sensory embedding.

Outlook

Demonstrator structures on a 1:1 scale are planned with aviation customers as well as the integration of VS half-sandwich technology into existing fuselage segments. Simulative and experimental studies on buckling and crash performance complement the development.